Reshoring Has Many Benefits – Here’s How Mirian Solutions Can Help

Now more than ever, companies who have depended on offshore manufacturing are looking at reshoring to reduce risk, improve supply chain resiliency, reduce held inventory costs, and reduce or eliminate the need for overseas travel to offshore facilities. In fact, a recent poll by Thomasnet from May 2020 showed that 64% of companies report they are likely to bring manufacturing production and sourcing back to North America. Will you be joining them?

Be Sure To Consider Total Cost of Ownership (TCO)

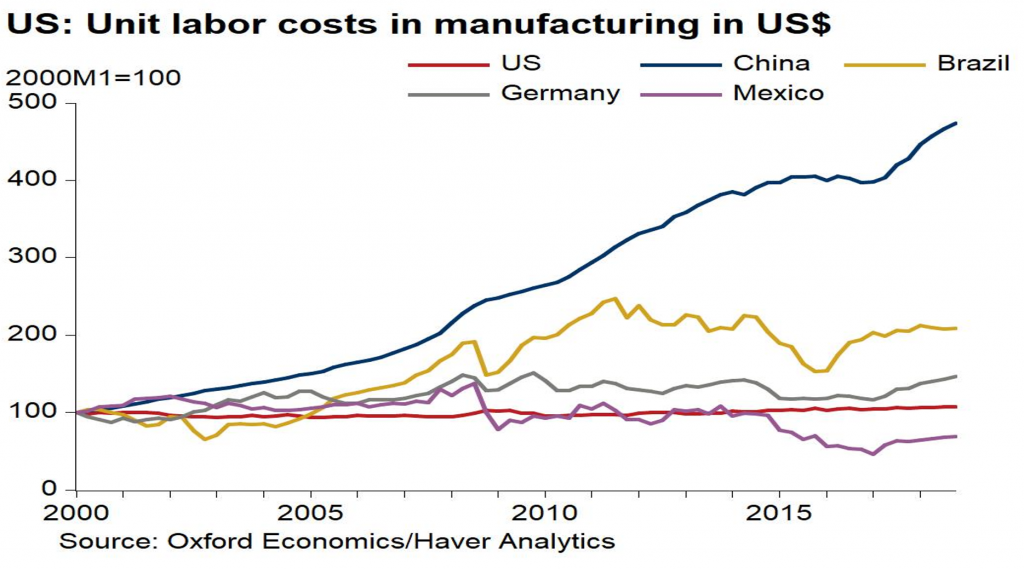

Historically, unit price has been the primary driver for offshore manufacturing. A recent study showed that almost 55% of respondents stated that price was the biggest factor in their decision to offshore their manufacturing. In recent years, the price gap has been closing. The cost of labor in China has been steadily rising, and at a faster rate than almost anywhere else in the world. This is helping to bring the actual unit costs closer together.

Beyond the unit costs, it is important to consider the Total Cost of Ownership (TCO) for all resources required to support offshore manufacturing. The ReshoreNow Initiative has an excellent outline of the hidden costs of offshoring when evaluating TCO, and even a free TCO calculator to help illustrate the costs. When evaluating TCO, consider the following hidden costs:

- Required travel to establish new offshore manufacturing relationships.

- Required travel to launch new manufacturing runs.

- Required travel to audit and maintain existing manufacturing projects.

- Economic risks of changes to trade agreements, including duties, tariffs and other fees.

- Higher inventory carrying costs due to higher minimum order quantities and longer lead times.

- Reduced cash flow with fewer annual inventory turns.

- Reduced agility to respond to customer demands without substituting sea freight for expensive air shipments.

- Potentially increased Intellectual Property (IP) risk and exposure.

Organizations that have evaluated TCO beyond the basic unit cost have often found that these hidden costs can add 20-30% or more to the cost of the product, often eliminating the perceived cost savings when evaluating the only the unit cost.

Travel Restrictions & Supply Chain Delays

COVID-19 continues to significantly impact the business operations of organizations around the world. Many regions are starting to see new increases in the number of positive cases, which is resulting in further restrictions and closures. As we head into the Winter months, many experts expect this trend to continue. Those that continue to offshore will see additional strain placed on their supply chain.

What if it’s months before you can physically visit the offshore facility to audit operations or launch new projects? What if shipping impacts such as container shortages and reduced shipping schedules continue to raise the cost to move your products from different parts of the world? What if there is reduced demand for your product due to the economic impacts of COVID-19 or other future events, but you’re already committed to an additional six months or more of inventory? What does that do to your inventory cost and balance sheet?

Mirian Solutions Can Help

Let Mirian Solutions help you review your options for reshoring your manufacturing to reduce risk, increase agility, and improve your overall business continuity. With many years of experience helping other companies reshore their products, we have the team of experts that can help you do the same.